Today’s parcel operations face unprecedented package volumes and growing customer expectations for fast and accurate delivery. These operations also face great labor challenges. High turnover and labor costs make automated alternatives to repetitive tasks like singulation even more attractive.

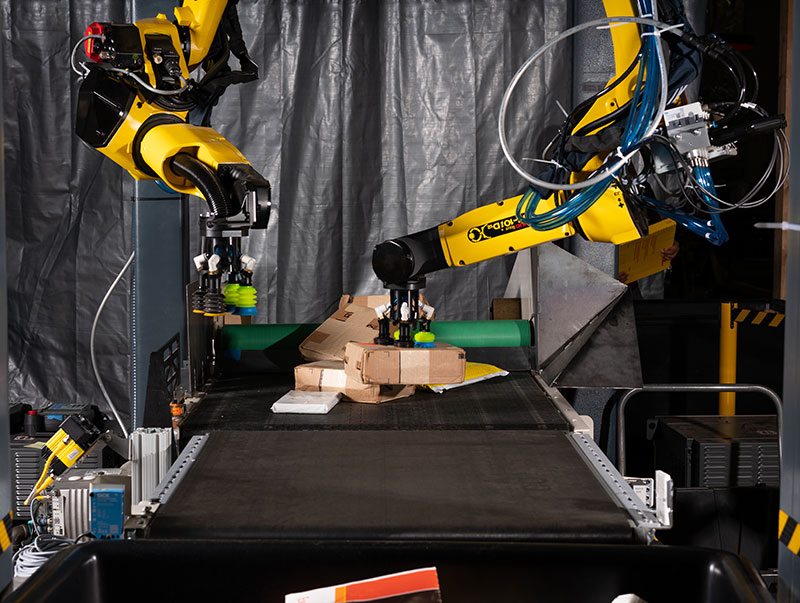

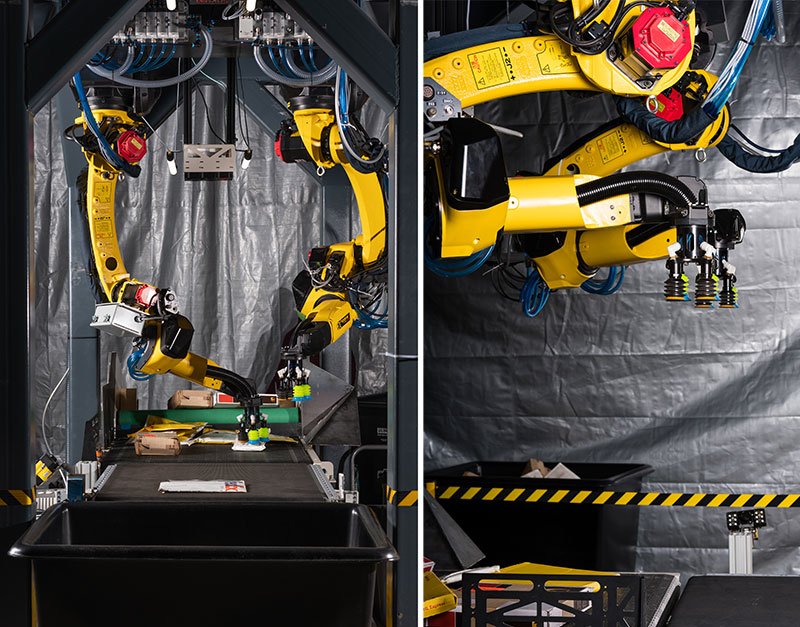

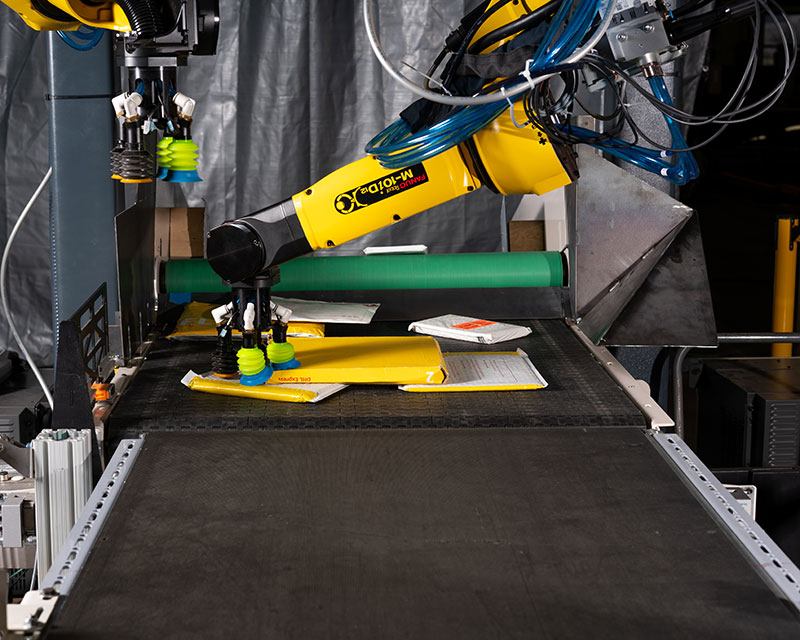

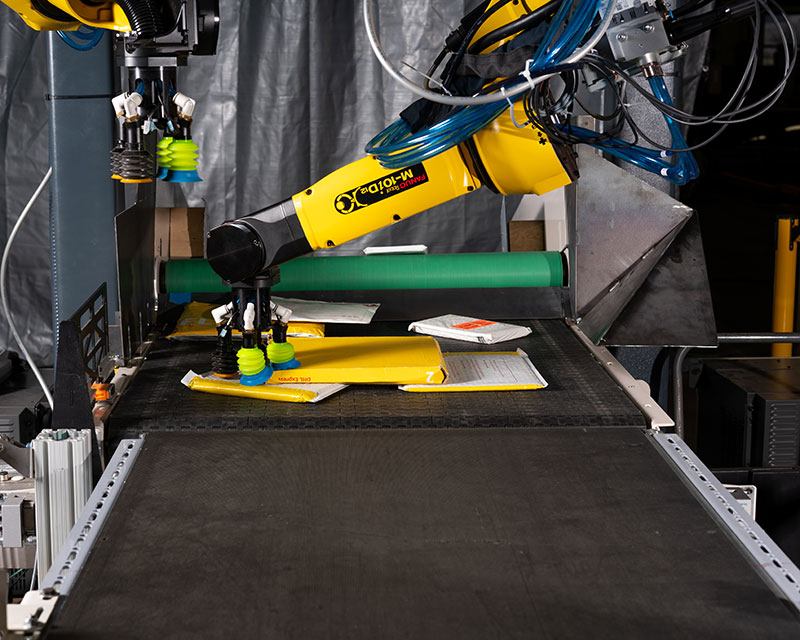

MHS’s dual robot singulator uses two six-axis robots working in tandem to convert bulk flow into a single-file stream of product ready for automated sortation systems downstream. A variety of end effectors accommodate a diverse range of product sizes and packaging. Powered by proprietary MHS vision and sensing technology, the solution is capable of singulating up to 3,000 parcels per hour. Built-in rejection pathways address out-of-spec packages and the solution also integrates seamlessly as part of larger automated systems, working in tandem with scan tunnels and MHS Helix WES for remote monitoring and control.

As customer expectations for fast delivery continue to grow, it’s more important than ever for operations to speed up their singulation to keep downstream sortation processes moving at peak efficiency and get orders out the door faster.

The dual robotic singulator harnesses the power of two six-axis robots working in tandem to streamline bulk flow of parcels into a single-file line of individual items for downstream automated sortation equipment. The singulation solution is compatible with a variety of end effectors to accommodate a diverse range of item sizes and packaging types. With a peak singulation rate of 3,000 parcels per hour and built-in rejection pathways for out-of-spec packages, this robotic solution is designed for the needs of modern logistics operations – boosting throughput and accuracy while reducing labor dependency.