Emeryville, California,

United States

(510) 367-5454

covariant.ai/ Covariant Company Profile

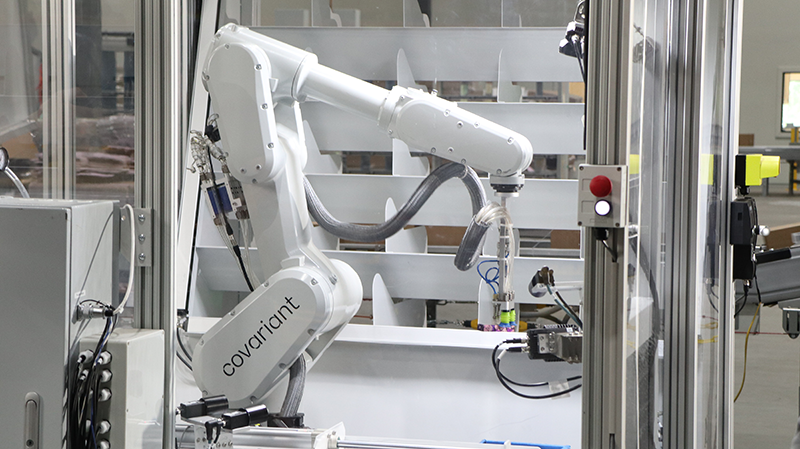

The incredible power of the Covariant AI Robotic Putwall stems from both the Covariant Brain and the robot cell design. The combination of these two elements outperforms classical automation. Classical automation has significant limits, especially within dynamic environments. With AI-based automation, robots learn by leveraging past experiences to see, understand, and continuously adapt.

By combining deep-learning neural networks with vision-based perception, the Covariant Brain gives robots the ability to perceive, think, and act when it comes to pick-and-place actions. Also, it keeps improving, informed by experiences from Covariant’s entire fleet of robots. Because it is informed by millions of interactions, the Brain is able to pick and place any item, regardless of shape, size, packaging, and environment. It can also be applied to a wide variety of applications that require picking and placing items in a warehouse.

The robot cell that the team designed from the ground up is the other differentiator. It maximizes speed and accuracy while also being flexible enough to integrate into a customer’s unique environment and workflow.

Robots can be driven by hard-coded programming to achieve classical automation, but modern AI-powered robotics can achieve true autonomy at scale for better efficiency and cost-savings.

3PLs and retailers are being pushed to the brink. Purchasing is at an all-time high while at the same time, supply chains are struggling with a labor shortage. The pressure is unsustainable without the help of intelligent technologies like the Covariant AI Robotic Putwall. It enables retailers, brands, and 3PLs to fulfill orders with optimum productivity and efficiency while also reducing costs. Using the autonomous putwall, fulfillment centers can complete more orders, at a faster rate, and operate 24/7. In current deployment, Covariant’s putwall has been performing at over 500 PPH with 99.96% perfect order rate.

The end-to-end robotic system is powered by the Covariant Brain AI Robotics platform and includes the robot arm, vision system, scanners, conveyor system, and any other components needed to fit into the existing workflow. Covariant collaborates with clients to design, develop, and deploy systems to meet their specific needs.

From health & beauty and apparel to pharmaceuticals and general e-commerce merchandise, the Covariant AI Robotic Putwall is helping organizations keep up with demand and future-proof their systems for the ever-growing e-commerce demand.

True autonomous performance - The Covariant AI Robotic Putwall can operate autonomously with minimal human intervention. Powered by the Covariant Brain, the AI Robotics platform enables robots to see, reason, and act. The Brain’s AI model is informed by millions of picks across the entire fleet of robots, allowing it to handle virtually any type of SKU, shape, packaging, and environment. And as it experiences new items, it adapts and continues to learn.

Seamless integration into existing workflows - With robotic piece-picking at its core, each system fits into a customers’ existing warehouse workflow. The end-to-end solution includes the Brain, application software, vision system, robotic arm, end effector, sensors, scanners, conveyors, etc. It can be integrated into existing systems, like WMS and control tower, and upstream and downstream processes to add value immediately.

Future-readiness - Given the software-first approach, customers are able to leverage the AI learnings from the entire fleet of robots on any future applications outside of putwall, such as order picking, induction, de/palletizing, packing, kitting, etc. As the Covariant research team refines new methodologies, the updates are deployed via the cloud so systems are always up to date with the latest and greatest technologies, and ahead of