A Florida Air Force base (AFB) is tasked with providing logistical support for launch operations in the Eastern Range of the United States, securing national space activities at Cape Canaveral, Kennedy Space Center, NASA and commercial entities such as SpaceX.

The AFB is responsible for provision of deployment, vehicle operations/maintenance, transportation, fuel services, material management functions and household goods support. After installing vertical lift modules (VLM) in a nearby warehouse, the base increased space utilization while ensuring rapid and accurate access to inventory.

With launch logistics support well established, the warehouse had the knowledge and capabilities to take on the inventory for an adjacent Rescue Wing Air Force Reserve Unit. There was just one problem: They didn’t have the space. Increasing inventory by 25% would require additional space and staff to manage the inventory.

The existing warehouse consisted of drawer cabinets holding small parts and racking to store medium-sized parts, while larger oversized parts were stored on floor pallets or outside. Previously, one VLM provided secure storage for critical items.

The solution was to expand the VLM technology they were using for secured storage into the warehouse, moving 70% of the medium-sized inventory into seven VLMs (Kardex Remstar). Bulky items remained in pallet rack. The move freed up 3,800 square feet of floor space, easily accommodating the additional inventory.

The seven VLMs deliver parts directly to the workers, eliminating wasted time spent walking through rows of shelving looking for parts. The warehouse reports that it took on average four minutes to pick a part from the shelving area, compared to two and a half minutes from the VLMs. The VLMs have allowed them to increase inventory by 25% without adding additional staff.

Having parts delivered right to the worker at an ergonomic “golden zone” height (between the knees and shoulders) has eliminated risk of injuries associated with bending and reaching. In the previous racking they were not using the top two rows because it was too difficult to carry heavy parts up and down the ladder. Now, the space within the warehouse is fully used and all parts are easily accessible with the push of a button. They also eliminated excessive walking between locations.

View Order Picker Products and Accessories

Crown SP 4000 stockpickers

Crown SP 4000 stockpickers

Stockpicker ensures operator stability.

MO Series Order Pickers

MO Series Order Pickers

Ergonomic features packed into orderpicker.

OSX15 orderpicker

OSX15 orderpicker

Orderpicker powered by 24- or 36-volt battery.

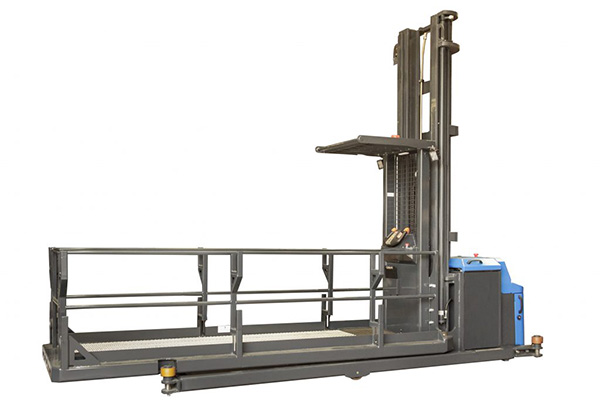

Combi-OP Orderpicker

Combi-OP Orderpicker

Handle long loads with orderpicker.

Model 8720 2nd Level Order Picker

Model 8720 2nd Level Order Picker

Strength and performance like no other.

R30XM narrow aisle orderpickers

R30XM narrow aisle orderpickers

Narrow aisle orderpicker increases productivity.

Article topics