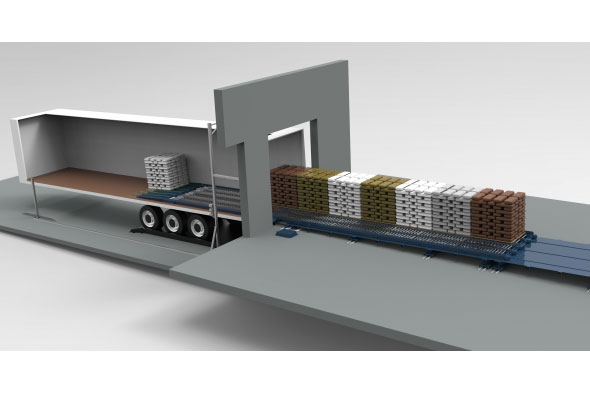

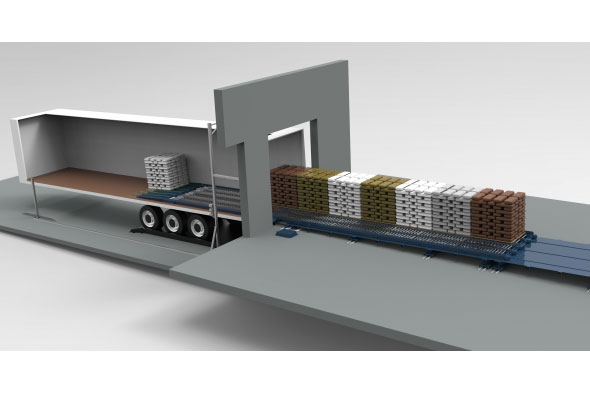

The Skateloader has been developed and engineered for the automated one-shot loading of either palletized or slip-sheeted goods, or both at the same time into non-modified trucks/sea containers. It’s ideal for distribution centers shipping high volumes of outbound, mixed product loads The Skateloader has two special functionalities for loading.

The system deposits the product carriers on the floor of the trailer in a controlled way, without any friction to the pallets and their cargo. The Skateloader can be seamlessly integrated into any automated production or warehouse system.

With this Skateloader the overall loading cycle can be reduced from ± 30-40 mins to around 7-8 mins which results that a single dock door handling 3 up to 4 full trailers per hour per dock. Save labor and equipment costs, improve logistics efficiency, improve worker ergonomics and avoid goods damage because no operator or manual intervention is required.

The Skateloader system is developed and engineered for the automated one-shot loading of either palletized or slip-sheeted goods, or both at the same time into non-modified trucks/sea containers. When trailer modifications are impossible, the Skateloader is the ultimate solution for one-shot loading of standard palletized goods or slip-sheeted goods for outbound transport. It’s an ideal solution for a high-volume production facility or a distribution center shipping to multiple end-users.

The total loading process only takes approximately 7-8 minutes. The Skateloader has special functionality for loading.

It is equipped with a scanning system controlled by software to ensure the correct and precise alignment of the loading system with the trailer. It can follow the trailer’s height which changes continuously while moving weight from the dock into the trailer, thus ensuring a flawless loading process. The system deposits the load on the floor of the trailer in a controlled way.

The Skateloader can be seamlessly integrated into any automated production or warehouse system. The Skateloader system increases efficiency by 400 percent, compared to traditional forklift truck loading. The shorter truck turnaround time at the dock is accomplished while creating a safer work environment, for employees and reducing the damage to the products.

Key Features: