Stoughton, Wisconsin, 53589

United States

1 (608) 205-1855 1 (800) 236-7130 x1855

www.palletreturndevice.com Automation Plus, a Division of CSF Company Profile

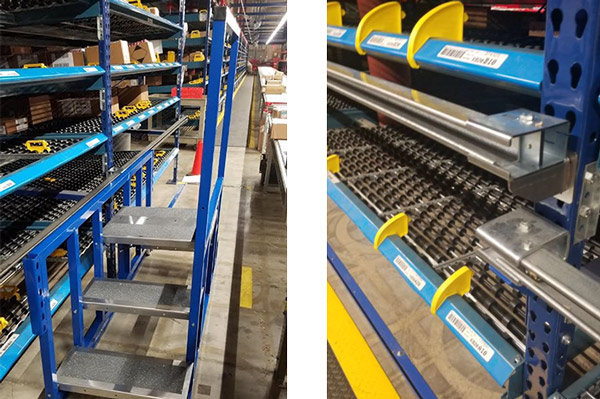

The Rolling Folding Racking Steps uses a combination of friction and gravity to open the steps for use, while a gas spring serves two purposes:

The steps are held in the closed position by an 88 pound-force magnet, with an optional latch assembly.

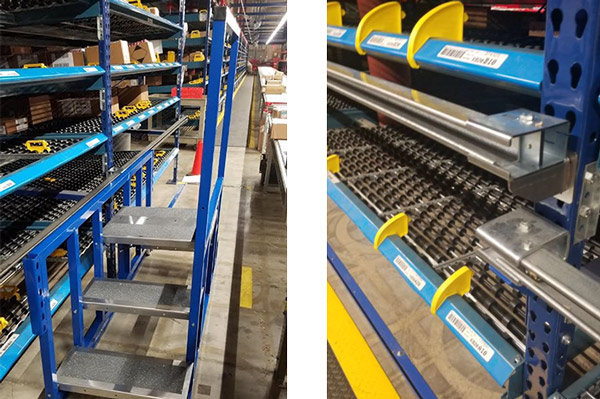

A unique roller system allows for easy mounting of the steps to the warehouse racking, as well as trouble-free travel along with the strut channel system. The steps are built using a combination of aluminum and steel in order to provide both strength and portability.

The Rolling Folding Racking Steps makes picking product from your warehouse shelves a breeze! The steps move along the warehouse racking with little effort and allow your associates to pick product easier from higher locations. Injuries are reduced by having employees pick product in their power zone and the inefficiencies of moving free standing ladders are eliminated. The steps allow for vertical expansion of your storage are by increasing the accessibility to higher shelves. The steps fold and unfold easily and safely, are held closed with a magnet system, and the gas spring keeps the steps from slamming down when opened. The trolley system used to move the steps along allows for you to mount your strut channel at different heights based on your racking configuration, and we can custom fit the system for most types of warehouse racking.

The Rolling Folding Racking Steps makes picking product from your warehouse shelves a breeze! The steps move along the warehouse racking with little effort and allow your associates to pick product easier from higher locations. Injuries are reduced by having employees pick product in their power zone and the inefficiencies of moving free standing ladders are eliminated. The steps allow for vertical expansion of your storage are by increasing the accessibility to higher shelves. The steps fold and unfold easily and safely, are held closed with a magnet system, and the gas spring keeps the steps from slamming down when opened. The trolley system used to move the steps along allows for you to mount your strut channel at different heights based on your racking configuration, and we can custom fit the system for most types of warehouse racking.

Custom UHMWP wheels are used to withstand the variations in any warehouse floor. When the ladder is not in use but in its open position, the wheels float just off the floor surface.

This product is nominated for the Product of the Year Awards