Jonesboro, Arkansas, 72401

United States

1 (870) 935-3700 1 (870) 931-1877

www.hytrol.com Hytrol Conveyor Co., Inc. Company Profile

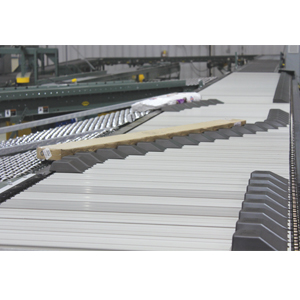

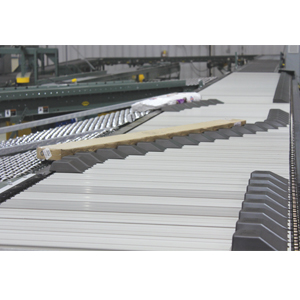

The ProSort 400 family of sorters by Hytrol handles high-speed applications with positive, gentle product diverting.

Offered in two models—with optional divert angles of 22 and 30 degrees—the sorters achieve speeds from 350 to 700 feet per minute. It diverts positively from either left- or right-hand sides with pneumatic or electric switches. For quiet operation, the sorter includes rubber isolators that can be easily removed for maintenance.

Features include plug-and-go wiring, minimum gap anodized aluminum slats, continuous polyurethane bearing track, high-efficiency gear motor, sealed and lubricated carrying chain, and wraparound shoe construction. Operation from induction point through divert confirmation is directed by Prologix controls, which also include sorter diagnostics functions.