Wilmington, North Carolina, 28405

United States

(910) 799-1100 (800) 830 9680

www.interroll.us Interroll Company Profile

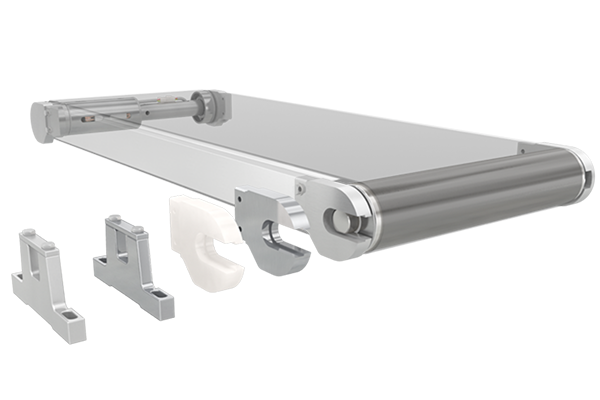

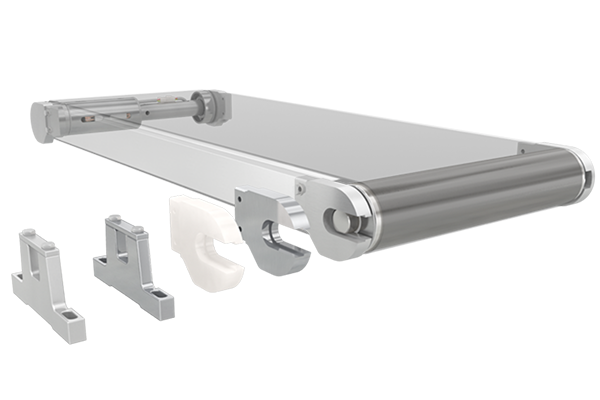

Interroll has set another milestone in its global innovation campaign with the launch of a new drum motor platform. The new generation of motors with fully modular synchronous and asynchronous designs are engineered for high performance and longevity, and to meet stringent hygiene requirements.

The modular platform strategy serves as the basis for the many benefits of the new drum motor generation, which will be used initially with all asynchronous and synchronous motor types with an 3.21” diameter, and expanded to the entire product range in the future.

Thanks to its modular flexibility, the new drive generation makes it significant easier to plan and implement highly efficient and user-specific material-handling solutions.

An extended number of gear stages broadens the range of speeds so that one drive solution is sufficient for all current and future uses. Furthermore, all options like encoders, brakes, or backstops are available for all motors.

The extended range of variants for the motors from 0.034 HP to 0.570 HP covers all conceivable uses in the food industry, material handling, and manufacturing.

All motor components are standardized, and thoroughly tested. For our customers this means shorter delivery times.

Since all motors have the same shafts, the variety of parts is reduced to a Minimum, resulting in a fundamentally easier conveyor construction - no matter if a synchronous motor or an asynchronous motor is needed. Replacement parts are available worldwide through Interroll and service partners provide fast and professional repairs.

The 30 mm shaft on Interroll’s new drum motors is significantly stronger, allowing for higher belt Tension as it does not bend even under higher load and at the same time, protects the ball bearings. The customers is on the safe side even with a non-optimal belt tensioning.

A stable planetary gear box delivers a high torque in all motors, holds up against bending, and resists against overload and impact load. The result is safer, more reliable operation.

All critical components and mechanical connections have been subject to stringent endurance testing. Our engineering laboratory’s expertise has been confirmed by practical tests with customers.