In a world truly obsessed with labor (un)availability and automation, the conventional warehouse continues to trudge on. You may even be managing one. But secretly, you probably have higher aspirations than to trudge.

And as much as you might like to read here how to make labor more plentiful, that’s not going to happen. Sorry.

But what you can find here are some tips on how to make your labor and processes more productive. So, we’ll focus on three key areas that can have a significant positive impact: rack, lift truck power utilization and safety.

As it turns out, that’s a mighty powerful trio. But before we get to those details, let’s look at the big picture of conventional warehousing.

The big picture

The biggest mistake any conventional warehouse manager can make is not thinking of the big picture first.

Yes, it’s all too easy to become overwhelmed by the incessant crush of constantly changing SKUs, order demand and focus on speed. Just getting through the day IS an accomplishment. But how you do it matters. And the better facilities got better with planning.

Talk to the experts and it’s clear that planning touches several aspects of warehouse operations. There’s the equipment mix, the layout, process flow, information availability and workforce, to name five key areas.

In interviews for this article, the need for a three-year planning horizon was common.

“Planning three years out allows for a gradual increase of improvements zone by zone in the warehouse. Smaller companies are typically on the shorter end of that time frame while larger companies are on the longer end,” - says Steel King’s Ryan Wachsmuth, dynamic storage sales manager.

Ian Hobkirk, senior vice president of consulting business development at KPI Solutions, says every conventional warehouse needs a master plan. “That sets the stage to determine which levers need to be leaned on first to elevate the most common benchmark of performance—productivity or output/hour,” says Hobkirk.

He explains this key benchmark is ultimately based on pick rates or lines picked per hour per worker. Fortunately, most conventional warehouses have at least some data here.

In addition, Hobkirk refers to a general body of data he calls “tribal knowledge” to benchmark current performance levels against those desired. Tribal knowledge ranges from talking to the people who actually do the work in your facility to widely shared public benchmarks by industry.

“It’s imperative for warehouse mangers to educate themselves and their staff about the true performance level of their operation,” says Trevor Bonifas, general manager of motive power at lift truck manufacturer Crown.

And while he was referring to lift truck power utilization when he made the comment, Bonifas would be the first to say his comment is true for all aspects of warehouse operations.

While conventional warehousing is typically focused on the equipment from docks and racks to lift trucks and even some conveyor, no operation can be effective without data and information about itself.

While most facilities are well past pencil-and-paper data management, bar codes, mobile devices and software are the next stage. Key software elements include warehouse management software (WMS) to run the operation, labor management software (LMS) to manage people and slotting software to ensure inventory is stored and staged to maximize workflow.

Wire mesh panels protect people working on mezzanines as well as objects from falling off the mezzanine.

And now we’ve come back to workforce. Hobkirk cuts to the bottom line quickly when he says “high turnover and low morale will kill even the best warehouse processes.”

He places a great emphasis on not just hiring quality people and paying them a competitive wage, but offering them a path to being recognized, promoted and having a career path in that conventional warehouse.

If you think all that is obvious, it’s not, judging from walk throughs of hundreds of facilities, says Hobkirk. “You can see good morale. It looks and feels different than those facilities without it. You can walk through and know when people think this is a good place to work. People know when management takes an interest in them and willingly show it even to strangers like me,” he adds.

With the big picture set, let’s focus on rack, power utilization and safety.

The right rack

Even though most conventional warehouses start with static selective pallet rack, these facilities are anything but static, says Wachsmuth. He suggests a stepping stone progression of different types of rack to help a facility grapple with changes in products, volumes and throughput expectations.

Pallet flow rack provides higher density pallet storage than single-deep static rack.

As the starting point, static rack is one pallet position deep and often two pallets wide. It’s a simple putaway and retrieve with lift trucks of pallet loads, typically all of the same SKU. With a little help from slotting software and a WMS, the positioning of pallet loads of various SKUs can be strategically placed in the warehouse to maximize picking efficiencies.

The next step, Wachsmuth says, is typically pushback rack. This takes static rack and makes it two, three or more pallet positions deep. Pallets are placed on a cart at the front and pushed back by lift truck.

“This is higher density than static rack because it replaces aisles with pallet positions,” says Wachsmuth. It’s also first-in/last-out storage, limiting accessibility of pallets depending on their loading sequence.

Next up is first-in/last-out drive-in rack. This loads from the front, but is configured so a lift truck can drive into each aisle, leaving the pallet in the open position closest to the front of the rack face. Drive-in rack is especially suited to pallet loads of the same SKU given the lack of accessibility to the ones loaded in first.

And then you have pallet flow rack. This first-in/first-out rack is loaded from the back with the pallet on a cart that slides downhill to the position furthest forward in the lane.

Wachsmuth says pallet flow rack lanes can store as many as 30 pallets deep. While that maximizes storage density, it also is best suited to a large mix of SKUs on pallets with much the same weight and footprint.

The graphic on page 55 offers a guide to working through these pallet rack types and inventory mix to maximize conventional warehouse efficiency.

Power utilization

Getting all those pallets into all that rack is where power utilization for your lift trucks comes into the picture.

Needless to say, several options for lift truck power systems range from internal combustion engines to hydrogen fuel cells. However, the majority of lift trucks in use today are electric, relying on either lead acid or lithium-ion batteries. The former dominates, but a clear growth trend is to lithium-ion. And it’s a battle.

“For electrics, the focus is simple,” says Bonifas of Crown. “Once you pull one kilowatt hour out of the grid, how can it be used for maximum efficiency and cost effectiveness.”

Crown and other lift truck suppliers offer considerable information to help you understand your operations and the value of the power options available. Bonifas recommends a power study to determine your power consumption habits, specific lift truck needs and most suitable power source.

“It all comes down to determining productivity based on power consumption and cost for each kilowatt hour consumed. It comes down to determining the run time a lift truck is getting for a specific battery charged at a specific rate,” Bonifas explains.

And the right answer here has a value. Just ask Shaun Feraco, senior vice president of operations at City Furniture. He converted from lead acid to lithium-ion for his fleet. With opportunity charging, operator productivity increased more than 12%.

The power of safety

Despite all the hardware and software needed to run a conventional warehouse, safety, both the equipment and the practice, is without question what keeps these facilities running day in and day out.

As Ray Niemeyer explains, accidents are more costly than is often recognized. Niemeyer is vice president of sales and marketing at SpaceGuard Products and chair of the ProGMA (Protective Guarding Manufacturers Association) at MHI.

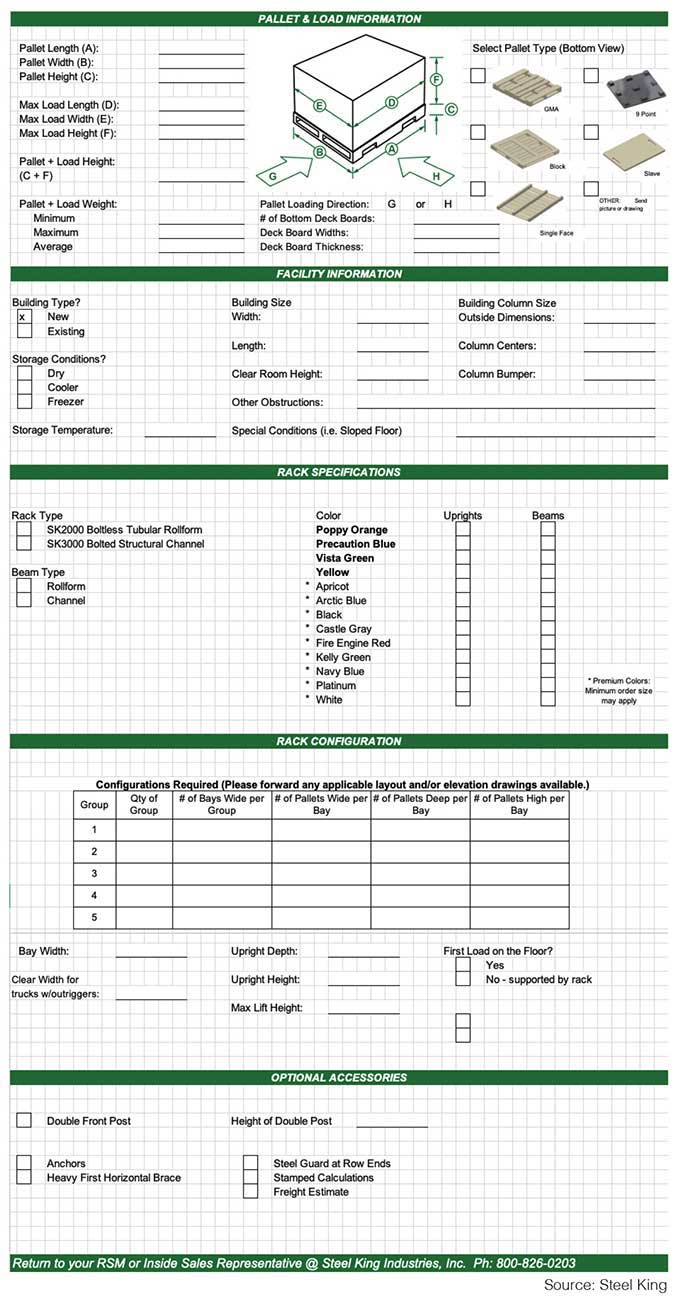

Rack selection should be guided by a summary of pallet, load and facility information for maximum effectiveness.

In 2020, the total cost of work injuries exceeded $160 billion, according to OSHA. Meanwhile, OSHA estimates that for every dollar spent on safety, six dollars in injury costs are saved.

ProGMA offers an extensive checklist (mhi.org/progma/checklist) of guarding devices available from docks to racks and even up to mezzanines for the conventional warehouse. These include dock door protectors, bumpers, safety netting, column protectors and wire mesh protectors to name just a few.

As Niemeyer points out, these devices are generally simple, but deliver significant safety in a conventional warehouse. They protect equipment as well as people, ensuring improved safety and fewer accidents.

It’s worth noting that safety may well require more than one type of protection. For instance, Niemeyer says a standard handrail system may provide sufficient safety protection for people on the edge of a mezzanine. However, wire mesh panels may also be required to prevent objects from falling from the mezzanine and injuring people below.

For a full review of safety equipment and practices suitable for conventional warehousing, visit mhi.org/progma for commentary, checklists and videos.

Racks, power utilization and safety are a powerful trio in any conventional warehouse. The challenge is to find the right mix to maximize productivity and throughput.

Article topics

Learn More