The new TX2 line of collaborative robots can be customized to accommodate the needs of specific industries, including medicine, pharmaceuticals, biotechnology, food, electronics, semiconductors, cleanrooms, laboratories and other challenging industrial environments.

Compatible with Industry 4.0 initiatives, the robots are capable of handling loads from 4.4 to 33 pounds and reach distances from 20 to 57 inches.

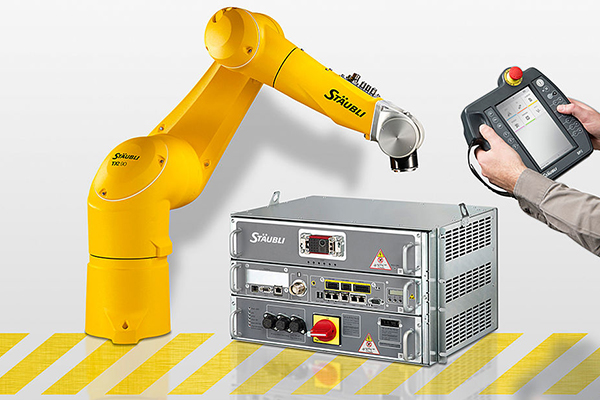

For safety, the six-axis robots have a separate safe digital encoder for each axis and an integrated safety board.

Features

Eliminating complex cable management

All cables and tubes run directly through the forearm, eliminating obstacles in the work area and ensuring the robotic arm has complete freedom of movement.Optimum use of the work area

The compact size of Stäubli robots reduces their footprint. With their large work envelope, they are designed for a wide variety of applications.Work in difficult environments

To meet the needs of all markets, our robots come with an optional vertical cable outlet. It is located underneath the base for optimal protection of connections in sensitive environments.High precision, long life and reduced maintenance

Stäubli is the only robotics manufacturer to make its own reduction gear systems, specifically designed to cut down on maintenance and extend the life of the robot.Flexible integration on the production line

For greater flexibility, Stäubli robots have multiple mounting configurations (floor, wall, or ceiling) to make it easier to integrate the robot into the production chain.