Farmington Hills, Michigan, 48331

United States

248-553-1000

www.daifuku.com/us Daifuku North America Holding Company Company Profile

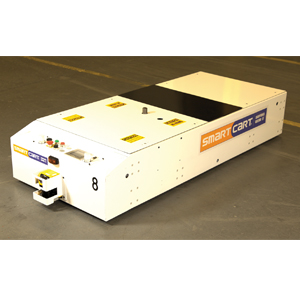

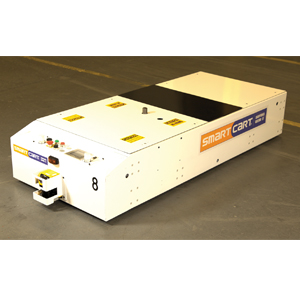

The new SmartCart model 300 Tugger Tunnel (300 TT) by Jervis Webb (Daifuku Webb) has been added to the supplier’s line of automatic guided carts.

Engineered to move heavier loads, the 300 TT can tow up to 3,500 pounds—1,500 pounds more than the previously introduced 100 TT, which tows loads up to 2,000 pounds. The new tugger ACG measures 31 x 74 x 14 inches and comes with an automatic hitch for coupling and decoupling carriers.

The entire SmartCart line of flexible, low-cost AGVs are ideal for use in assembly lines, to deliver pallets to and from stretch wrappers, roller conveyors and palletizers, and to move loads around a facility. Navigation and troubleshooting software enable users able to make their own changes to the system and to troubleshoot problems without outside assistance.