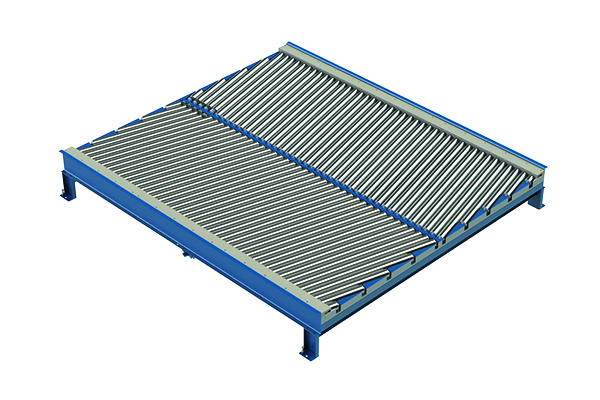

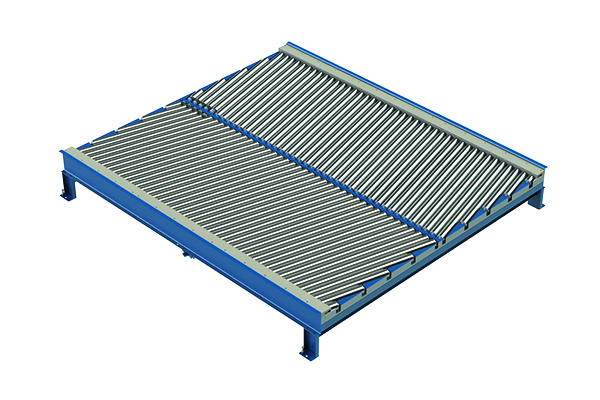

Creating a more positive drive arrangement than O-ring driven rollers, a new line of poly-v belt driven roller conveyors include roller assemblies with the supplier’s patented grooved hubs and mounting method, driven by matching grooved belts.

Ideal for 24-volt DC motor-driven roller and flat motor zoned accumulation configurations in high-speed applications, conveyor rollers may be specified in 1.9-inch or 2.5-inch outer diameters.

They handle loads up to 2,500 pounds and reach speeds in excess of 800 feet per minute. Featuring tightly packed roller spacing, system configurations include merge and alignment conveyors for handling small packages and poly bags.

EFFECTIVE WIDTH: 6”- 48”

BEGINNING ELEVATION: 7” - 120”

LENGTH: 36” - 240”

ENDING ELEVATION: 7” - 120”

SPEED: 15 - 110 FPM

ROLLER CENTERS: 3”, 4”, 6”

DRIVE: Standard drive is mounted near the center of the conveyor length on belt guard side. Up to 20 conveyor rollers can be driven from each side of the drive roller. Additional drives are required to extend the conveyor length.

FRAME: Standard frame includes 5” channel on chain box side and 3-1/2” channel on opposite side with roller set high in frame. Optional frame includes 5” channel on opposite side with roller set low in frame.

MOTOR: 1/2 HP through 2 HP, Energy efficient and inverter duty motors are also available along with Motorized Drive Rollers (MDR). voltages include 115/1/60, 208/3/60, 230/3/60, 460/3/60 and 575/3/60 along with DC voltages for MDR drives.

ROLLERS: Standard galvanized roller - 1.90” diameter, 16 ga wall tube with 7/16” hex cold rolled steel axles, spring retained. Standard bearings are ABEC precision, grease packed. Rollers include Poly-V sleeves for (4) rib belts.

ROLLER COVERS: Optional roller covers include polyurethane roller sleeves, Ultrex accumulation sleeves.

SUPPORT CENTERS: Standard supports are heavy duty floor supports on 10’ centers. Optional 4” formed channel with jack bolt adjustment.

FRAME FINISH: Standard finish is OSHA safety blue powder. Optional colors include green, beige, gray, orange, black and yellow.