Ridg-U-Rak, Inc.

North East, Pennsylvania, 16428

United States

866-479-7225 1 (866) 479-7225

www.ridgurak.com Ridg-U-Rak, Inc. Company Profile

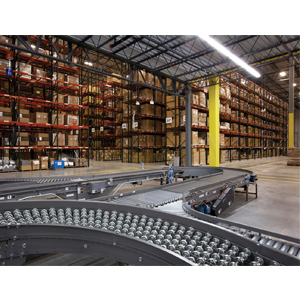

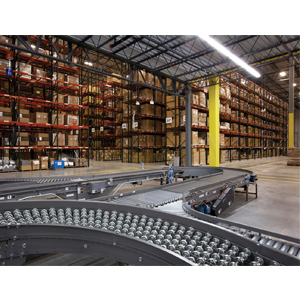

Using a flow-through concept, a line of custom-engineered pick modules by Ridg-U-Rak—incorporating a lift truck aisle on one side of the system and an order picking aisle on the opposite side—can support complex picking operations and maximize facility space.

The system also incorporates multi-level picking with a range of mezzanine, flooring and decking selections to better optimize product flow. The pick modules use a variety of pallet and carton flow rack choices, including push-back, gravity flow, selective pallet rack and other storage methods, as well as conveyors.

Ideal for high-throughput, high-volume order fulfillment and distribution operations, the installation allows product loads to be moved from pallet racks before being broken into cartons and pieces, where they are sent to pick areas for processing and shipment.