North Reading, Massachusetts, 01864

United States

(978) 664-9205

www.frommeltequipment.com/ Frommelt Safety Products Company Profile

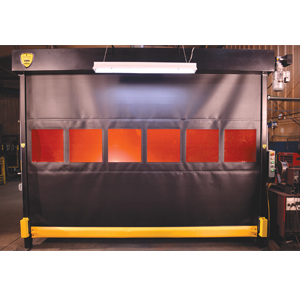

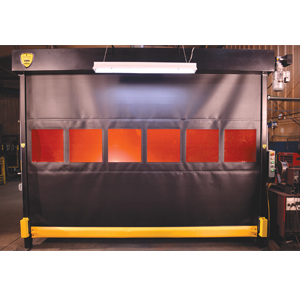

The Guardian Defender high-speed, high-cycle automated barrier door by Frommelt Safety Products protects employees from automated stretch-wrap machines, as well as other robotic machine movement zones.

It also contains fumes, sparks, smoke, mist, flying debris, excess noise and other manufacturing process by-products, making it ideal for robotic welding cells, automated assembly and palletizing/packing machinery. To minimally intrude in the footprint of a manufacturing cell, the door features roll-up construction.

Other highlights include a hold-down mechanism to lock the door in a down position during machine de-energizing; reconfigured rotary cam limit switch, encoder positioning and variable frequency drive to control operating speed and position; and non-contact interlock switches.