The StakPak PLUS takes all the best attributes of the traditional StakPak container, including reusability and cost savings, and combines them with customized heights to increase container capacity, providing transportation efficiencies, cost savings, sustainable advantages and more. A customizable solution, the StakPak PLUS design combines traditional totes with various collar sizes to increase height for unique shaped parts. This custom design is especially important in the electric vehicle supply chain where there’s a frequent need to transport uniquely sized parts.

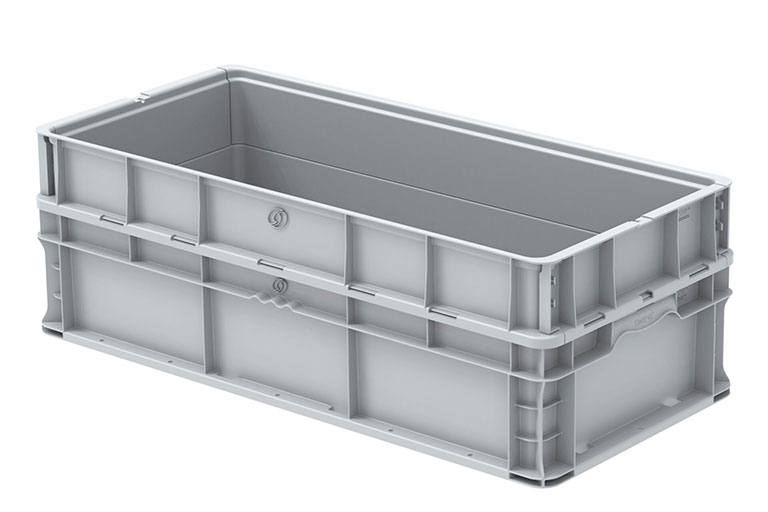

The StakPak PLUS offers maximum durability with vertical corner rib structure. For easy manual handling, the StakPak Plus is a lighter weight solution than alternative custom totes and offers a contoured, ergonomically-friendly handle. In implementing this solution, companies can reduce the environmental waste associated with single-use corrugated boxes, and at the end of its long service life, the StakPak PLUS collar is 100% recyclable and can be reprocessed right back into supply chain packaging.

Designed to meet the needs of industrial and automotive supply chains, the StakPak PLUS totes are not only built for strength and durability, but also to accommodate the unique shaped parts commonly found in these applications. With increased height comes increased cubic capacity, allowing for more parts to be transported per container. Smooth interior walls make for ideal dunnage integration to provide better pack density and part presentation. Available in popular 32” x 15” and 24” x 15” footprints, the StakPak PLUS cubes out a standard 45-by-48-inch plastic pallet. The StakPak PLUS offers customers a lightweight, sustainable solution that helps companies protect parts, optimize line-side assembly operations and meet their supply chain’s evolving needs while simultaneously reducing lead times associated with a custom tote.

Since the introduction of the StakPak container, it has evolved into an entire family of straight-wall modular containers designed for just-in-time applications for parts shipping, storage, work-in-process and line-side assembly operations. In fact, StakPak containers have traveled 25 billion trips in supply chains over the years.