Wilmington, North Carolina, 28405

United States

(910) 799-1100 (800) 830 9680

www.interroll.us Interroll Company Profile

Able to handle more than 20,000 conveyed goods an hour, the MX 025H Crossbelt Sorter enables a wider array of goods to be sorted, especially those that are heavier and larger.

Aside from its high sortation capabilities, the sorter can also convey at a speed of up to more than 8 feet per second, more than 2 feet per second faster than the ST 6160. In addition to its increased conveying speed, the MX 025H can also transport goods that weigh up to 110 pounds.

Its carriers’ width has augmented by 50% when compared to other crossbelt sorters, offering users more flexibility as they sort goods that have a variety of dimensions. And, due to its rubber belt, the MX 025H doesn’t need lubrication, reducing maintenance costs

Today, over 400 Interroll Crossbelt Sorters are already in use worldwide by industry leaders such as Amazon, DHL, FedEx, UPS, Hugo Boss, Inditex (ZARA), Zalando and the Swiss, Austrian, and Chinese postal systems. Less complex control systems are used for this automation solution.

Therefore, there is no need for expensive installation, maintenance or reconfiguration expertise for the systems. The unique design principle ensures maximum availability, a very long system service life, low operating costs, and fast return on investment.

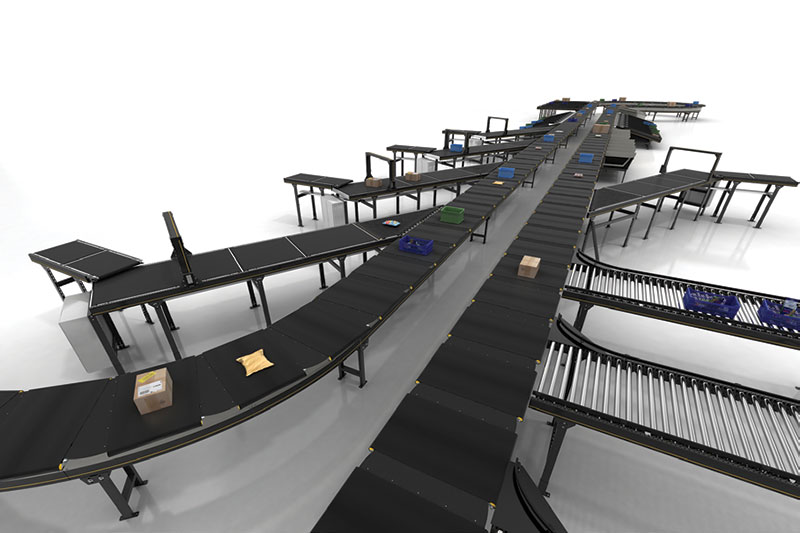

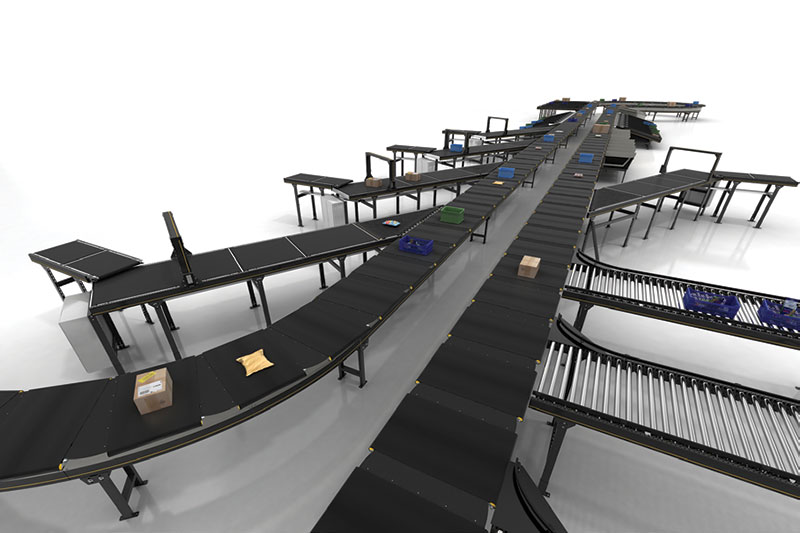

With the horizontal crossbelt sorter, goods can also be transported in curves and up or down slopes. This makes for an extremely flexible, three-dimensional sorting system. The vertical crossbelt sorter has a space-saving design and enables precise discharge and careful transport.