Chicago, Illinois, 60160

United States

1 (708) 344-9999 1 (877) 216-0612

www.interlakemecalux.com Interlake Mecalux Company Profile

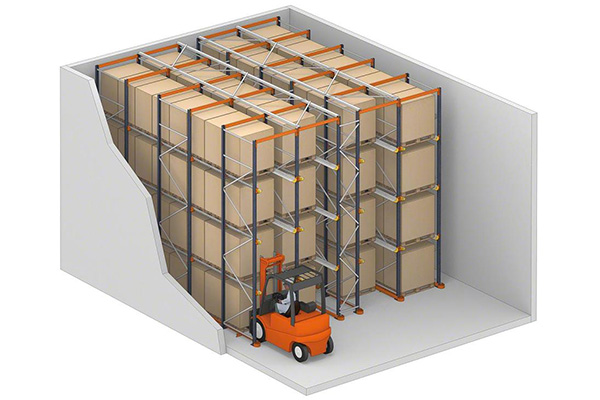

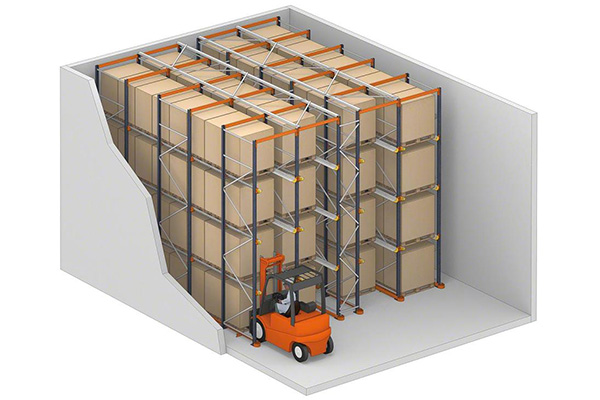

Ideal for stocking large quantities of relatively few product types, a line of drive-in/drive-thru roll-formed pallet rack by Interlake Mecalux can reduce overall square footage needs by 35%, compared to selective rack.

Highly customizable, the rack structure can be configured for last-in/first-out (LIFO) or first-in/first-out (FIFO) storage applications.

Because it features deep lane storage, the racking reduces space requirements and costs by holding more loads. The structure is engineered to accommodate a facility’s existing pallets and forklifts in a variety of heights and depths.

Drive-in racking and drive-thru systems are exceptionally suited to large stocks of relatively few product types. Use this high density system to reduce overall square footage requirements by 35% or more, compared to a standard pallet rack configuration.