Grand Rapids, Michigan, 49546

United States

616-888-2595

www.tgw-group.com TGW Systems Company Profile

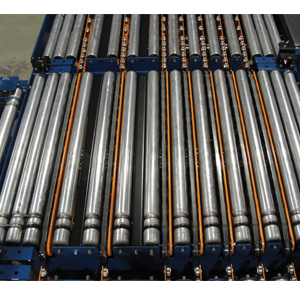

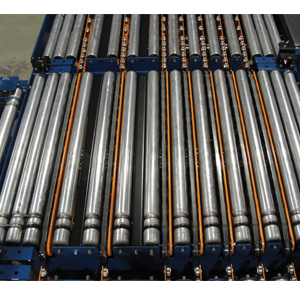

The IntelliROL system by TGW Systems employs a motorized roller to power each zone or segment of the conveyor. Modular and customizable, the conveyor can be easily reconfigured to address future needs.

Features include a low-mount roller frame that completely protects all of the pre-mounted, pre-wired electronic components. Start-up time is minimized by plug-in installation with pre-wired beds and pre-tested controls. To conserve energy, each motorized zone can be turned on only when needed, reducing noise levels and increasing component life.

Additional components, including pre-wired smart driver cards and photo-electric sensors can be configured for transportation, accumulation and work-in-process operations without additional controls processors.