Rice Lake, Wisconsin, 54868

United States

1 (800) 472-6703

www.ricelake.com Rice Lake Weighing Systems Company Profile

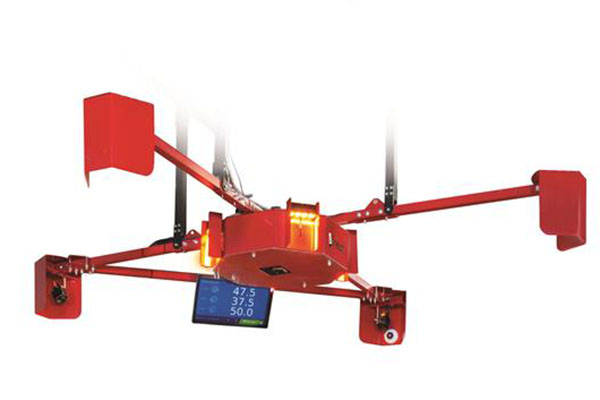

Featuring eight sensors, the iDimension LTL XL dimensioning solution can acquire crate and pallet measurements in less than 2 seconds. Created for freight that has oversized lengths, the solution can record Legal for Trade measurements on freight up to 12 feet long, 8 feet wide and 8 feet tall. Offering a solid-state design, with no moving parts, the solution requires very little maintenance.

It can be integrated into LTL freight handling environments and transfer shipment data to existing ERP, MRP, TMS and WMS systems, while using the iDimension SS for software integration. The solution uses TCP/IP cameras and can obtain high-resolution images of freight, enabling identification, condition assessment and tracking.

The iDimension LTL uses advanced sensing technology to accurately determine the cubic dimensions of freight. Its ability to capture NTEP Certified dimensions helps ensure freight code compliance and deters revenue-loss from miscalculated dimensions.

The iDimension LTL is ideal for LTL carriers and shipping departments with a high percentage of product shipped via pallet or crate. It removes the potential for human error and the extra labor of manually determining cubic dimensions by accurately capturing freight dimensions.

Up to two cameras can be added to provide images of the freight for visual verification of the freight’s condition at the time of measurement. Images can include dimensions and a time & date stamp.

With no moving parts and a solid-state design, maintenance of the iDimension LTL is virtually non-existent. The ceiling mounted system offers 360-degree access for easy pallet placement within the 8 x 8 feet target area. Its advanced imaging technology dimensions LTL freight at an incredibly fast rate of 2-3 seconds within 0.5 inch accuracy.

The operator display, mounted on the system, provides a visual of freight dimensions to the forklift driver. Once a pallet has been dimensioned, the L x W x H measurements and a “Remove” message is displayed to indicate the system has completed dimensioning and the forklift driver can remove the freight.

A Windows®-based software program and industrial touchscreen PC provide connectivity with bar code scanners, floor scales, and other networked devices to trigger the system to dimension. You can then transmit data and images for each transaction into your management system.