Springfield, Ohio,

United States

1 (937) 525-5533 1 (866) 258-8083 1 (800) 727-8774

www.konecranesusa.com Konecranes Company Profile

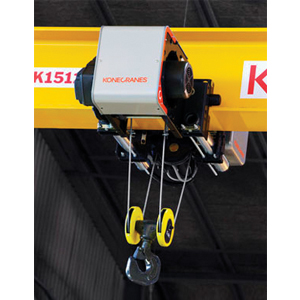

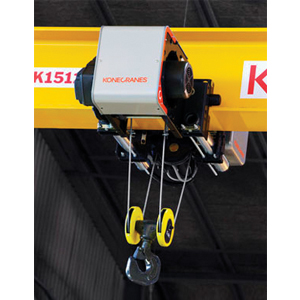

With its compact construction, the CXT electric wire rope hoist by Konecranes accommodates facilities with limited headroom above the crane, while maximizing the use of floor space.

The hoist can be custom-tailored to lift loads up to 80 metric tons. Features include a durable motor with a 60% duty cycle and rugged DC brakes that run for one million operation cycles. Easily accessed for maintenance, the hoists can be programmed with advanced intelligent functions, such as sway control, target positioning and protected area limits for total operator control over process tasks.

The hoists also limit horizontal hook movement for fast, accurate load positioning. To reduce maintenance costs and downtime, the hoist can be equipped with a remote monitoring and reporting connection that provides information about safety, operation, statistics and service life.