Bell and Howell

Durham, North Carolina, 27713

United States

1 (919) 767-4401 1 (800) 220-3030

www.bellhowell.net Bell and Howell Company Profile

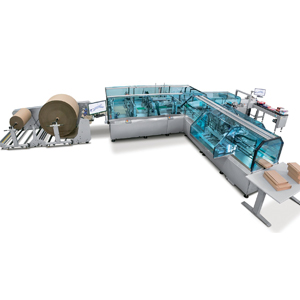

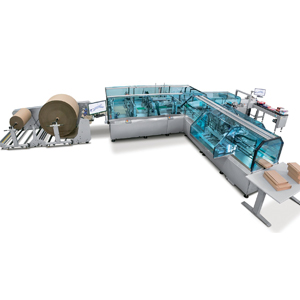

The CartonWrap system by Bell and Howell creates ready-to-ship packages by automating boxing and labeling at processing speeds up to 15 boxes per minute, without manual labor.

By sizing the box to its contents, the system significantly reduces shipping costs, as well as extra padding materials to fill empty space. As ready-to-package goods enter the system, the order is automatically identified and dimensioned. From this information, the system dynamically creates a custom-sized corrugated carton that wraps around the item, and then seals the carton and labels it for shipping.

Features include creasing and cutting equipment, a transversal cutting blade and hot-melt glue guns that apply glue to the die cut. All associated data can be applied to the carton, including product bar code lookup, document attachment, labeling, ink-jet printing and product weighing.