Lightning Pick

Germantown, Wisconsin, 53022

United States

1 (262) 250-2143 1 (800) 827-8878

www.lightningpick.com Lightning Pick Company Profile

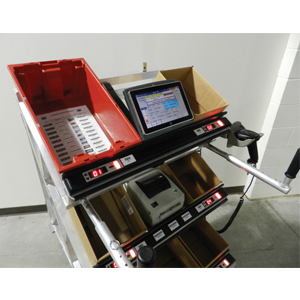

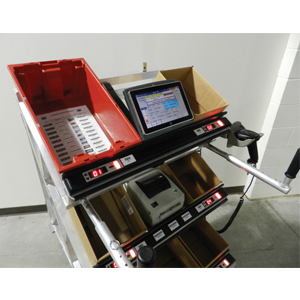

Providing up to 40% additional accuracy over paper-based or standalone picking automation, the automated batch picking cart by Lightning Pick Technologies includes a new version of software that maximizes the efficiency of each walk pass through the warehouse.

The software’s real location algorithm optimizes pick routes by selecting order combinations based on the cart’s real-time physical start location, instead of from a single pre-determined order drop/new batch launch location.

To maximize productivity, the system adds single pick orders to moving carts while individual order containers from the original batch are being filled. Communications are maintained with the server through the existing plant wireless LAN network.

ProMat 2013—Booth 3903