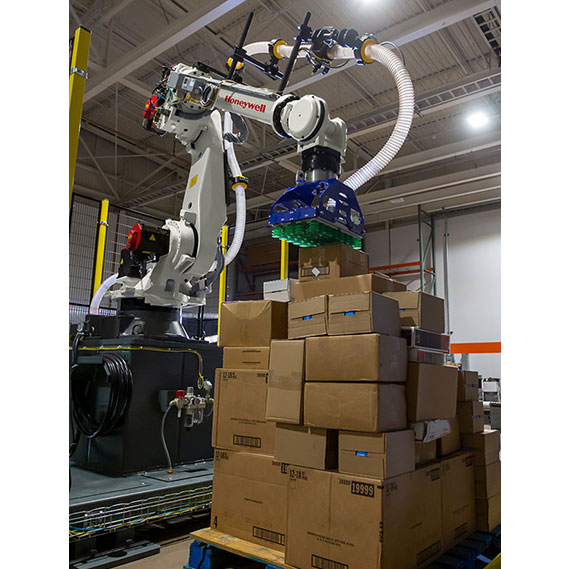

Able to handle items that weigh up to 80 pounds, a smart, flexible depalletizer has been developed to process single- and mixed-SKU pallets in virtually any sequence or pattern. Requirements for human supervision, along with additional programming—even while users work with unstable pallets—decreases.

Capable of supporting pallet heights of up to 8 feet without using a lift, the depalletizer detects item heights, while enhancing its motion path.

Featuring a perception system that automatically identifies and removes slip sheets, the depalletizer uses remote monitoring to enable an assortment of pallets to be handled, while allowing human-guided machine learning. Since it can concurrently pick several units, leading to a rise in ROI, the depalletizer improves throughput.

Honeywell Intelligrated - MODEX 2022 - Booth B7619a

Honeywell Intelligrated’s robotic depalletizers are designed to precisely move and place a wide range of product shapes and sizes. These modular solutions feature compact footprints that scale easily from a single robot to a large multi-arm system.

For maximum flexibility, our robotic depalletizer systems support robotic arms from multiple manufacturers, including Motoman, KUKA and FANUC. Standard and custom end-of-arm tooling options are designed and built in-house to ensure seamless integration. This complete solution provides fully integrated software and machine controls, including support for PLC-based systems and vision-guided robotic technology.

If your operations require quick product changeovers and frequent packaging changes, we offer flexible options for single case, row or layer handling. Try our simulation software for assistance determining system feasibility, while enabling efficiency testing, training and troubleshooting.