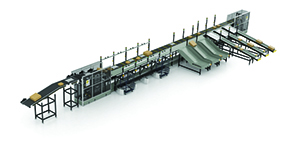

Interroll is one of the world’s leading manufacturers of key products for unit load handling systems, internal logistics and automation. These solutions are used primarily within the area of food processing, airport logistics, postal services, distribution and in various segments of industry. The products include easy-to-integrate drive solutions such as drum motors for belt conveyors, DC-powered and non-powered rollers for conveyor systems; energy-efficient flow storage modules for...

3000 Corporate Drive

Wilmington, North Carolina, 28405

United States

(910) 799-1100 (800) 830 9680

[email protected]

www.interroll.us Interroll Company Profile

Wilmington, North Carolina, 28405

United States

(910) 799-1100 (800) 830 9680

www.interroll.us Interroll Company Profile