Springfield, Ohio,

United States

1 (937) 525-5533 1 (866) 258-8083 1 (800) 727-8774

www.konecranesusa.com Konecranes Company Profile

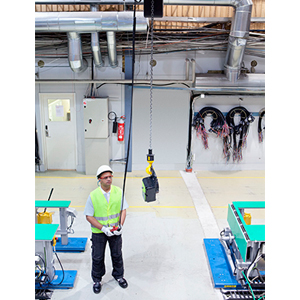

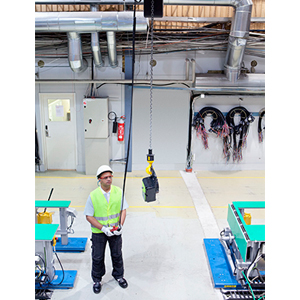

For manufacturing applications where high-speed load transfers and precise assembly work are required, the CLX electric chain hoist is offered by Konecranes.

Capable of handling capacities from 130 to 4,400 pounds, the hoist can be paired with workstation cranes, overhead cranes and jib cranes or deployed in a variety of fixed configurations. The hoist features an aluminum frame, maintenance-free transmission and patented five-tooth chain sprocket with intermediate teeth. Its oil lubrication-based transmission lowers operating temperature to boost power.

With a speed ratio of 6:1, the hoist’s fast movements correspond to faster work cycles. For enhanced safety and lower maintenance requirements, all electronics are placed on compact circuit boards to decrease internal wiring and limit the number of service parts.