Schunk

Morrisville, North Carolina, 27560

United States

(800)-772-4865

www.schunk.com/us_en/homepage/ Schunk Company Profile

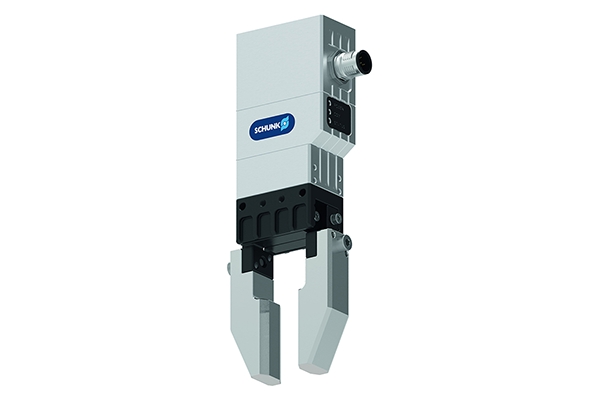

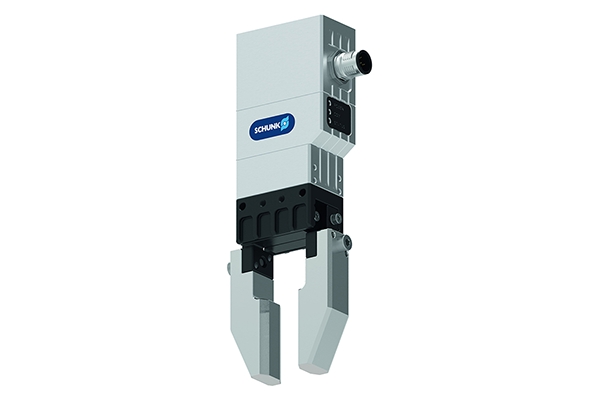

The use of compact, mechatronic 24 V small components grippers SCHUNK EGP with IO-Link enables flexible Pick & Place processes. It is based on the meanwhile tried-and-tested SCHUNK EGP and also scores with a high speed and at the same time high gripping force.

In the version with IO-Link, the electric small components gripper meets the IO-Link Class B Standard suitable for increased power consumption, and can be directly connected with an IO-Link Class B Master. Its gripper fingers can be freely positioned within every cycle, meaning maximum flexibility, and also due to the prepositioning the shortest cycle times can be ensured.

As the gripping force can be adapted to the respective workpiece using software settings in four stages, handling scenarios with deformation-sensitive parts can also be achieved. Within the permissible finger length, both the gripping force and the gripping speed remain virtually constant as does the speed over the entire stroke.

The position of the gripper fingers can be detected using the integrated measuring system over the entire stroke, meaning no external sensors are required for monitoring. Quite the opposite in fact: Intermediate positions or varying workpiece sizes can be queried at any time.

An integrated diagnosis tool permanently monitors the voltage, current, temperature, and condition of the gripper and automatically transmits errors to the higher level control system. If needs be, systems operators can also store maintenance intervals for the system on the tool.

As the entire electronics of the SCHUNK EGP is integrated in a space-saving way, the gripper doesn’t take up any space at all in the control cabinet. Brushless and therefore maintenance-free servomotors and a backlash-free preloaded junction roller guide ensure a high level of efficiency, constant gripping forces across the entire finger length and make the SCHUNK EGP with IO-Link a dynamic, precise, and powerful expert for challenging handling of small and mid-sized parts.

Just like its predecessor the pneumatic SCHUNK MPG-plus, the SCHUNK EGP can be screwed through or screwed either on the side or on the base, which increases its flexibility within a system design.

In order to increase the dynamics and the energy efficiency of higher-level systems, the gripper housing consists of a special high-performance aluminum. In addition, the design is rigorous in eliminating superfluous materials.

The Pick & Place expert seamlessly fits in the program for modular high performance assembly from SCHUNK. It meets protection class IP30 and is suitable for the most various applications in the area of small component handling and assembly.

The small components gripper with IO-Link is available in sizes 40, 50, and 64 with a finger stroke of 6 mm/8 mm/10 mm, and maximum gripping forces of 140 N/210 N/300 N. The repeat accuracy for gripping is 0.02 mm, for positioning the gripper fingers 0.1 mm to 0.2 mm, depending on whether the position is approached from one or two directions. The gripper is suitable for handling parts weighing up to 0.7 kg/1.05 kg/1.25 kg. In addition to the version with IO-Link, the 24 V gripper is available as before with actuation via digital I/O.