Warehouse Management TingTong, China

In 1998, the transportation department of Master Kong, a well-known FMCG company, spun-off to form a new logistics company, Tingtong.

In 2004, Itochu Corporation, a Fortune Global 500 company, became a shareholder of Tingtong Logistics.

In addition to Shanghai, Tingtong established branch offices in Beijing, Guangzhou, Chengdu, and Shenyang, and has 56 self-operated distribution centers throughout China.

As a professional, large-scale integrated third-party logistics company, Tingtong's main focuses are FMCG logistics, sophisticated logistics, and retail consolidated warehouse logistics, as well as e-commerce logistics. Tingtong's main clients are all industry leaders.

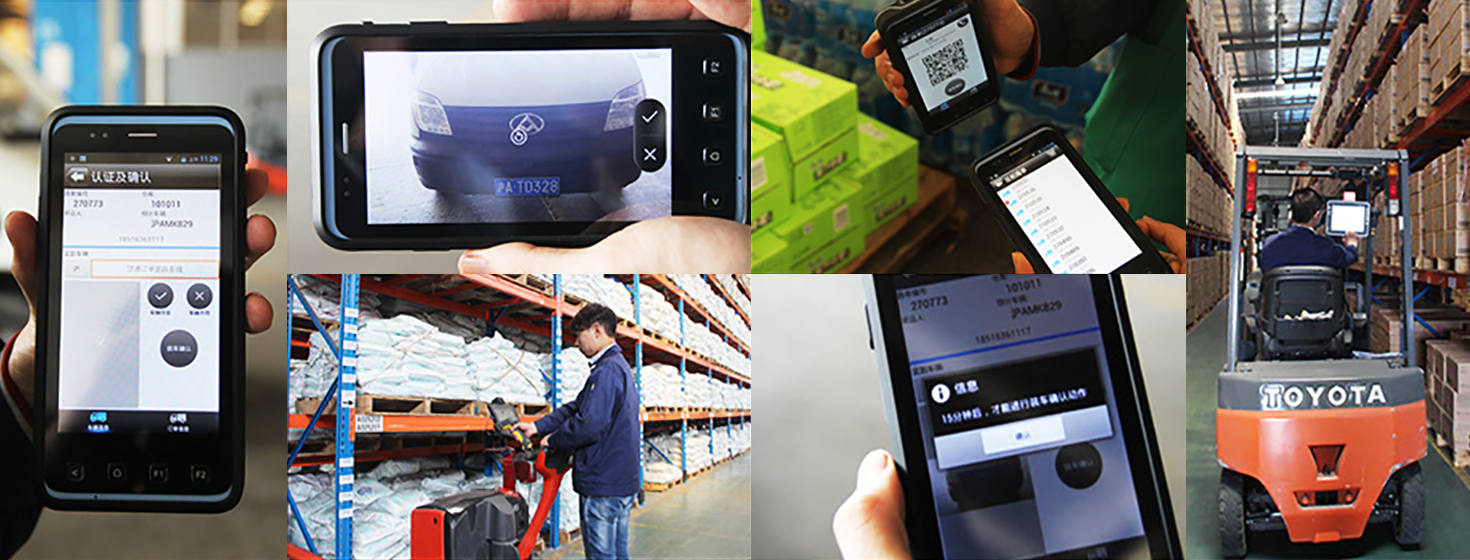

InTingtong Logistics' warehouse, staff drive forklifts, pallet trucks, and order pickers to store stock and pick orders in an orderly fashion.

In the past, whenever there were picking lists, administrative staff would hand a stack of picking lists over to the warehouse staff.

Today, warehouse staff obtain this information through handheld devices to begin loading operations. With the help of onboard computers and large remote barcode scanners, staff no longer need to memorize a bunch of numbers in advance to accurately locate the required shelves, goods, and quantities, or leave their the trucks to scan barcodes.

After picking, the system will automatically update the inventory in real time, let the picker know which exit and which pallet to place the goods via the computer, and even automatically arrange for orders with nearby delivery locations to be placed on the same delivery truck.

Tingtong can also track the location and driving route of each truck through the newly introduced order tracking management system in real time. The company can also obtain real-time delivery completion updates of trucks and stores.

When talking about the changes in Shanghai Tingtong's warehouse operations, Tingtong Logistics' Assistant Vice President Mr. Huang said:

“With the rapid growth of the Chinese economy, wages in China are also growing. The logistics industry is characterized by high requirements for human resources and low margins. This puts a lot of pressure on Tingtong. If logistics companies want to increase profits, they must rely on advanced technology to optimize and monitor warehouse operations and the transport and delivery of goods, thus reducing the number of operational aspects such as work hours, losses, and the consumption of other resources throughout the entire logistics process. This would help improve the logistics companies' overall operational efficiency. This is also why Tingtong introduced Advantech's digital logistics solution.”

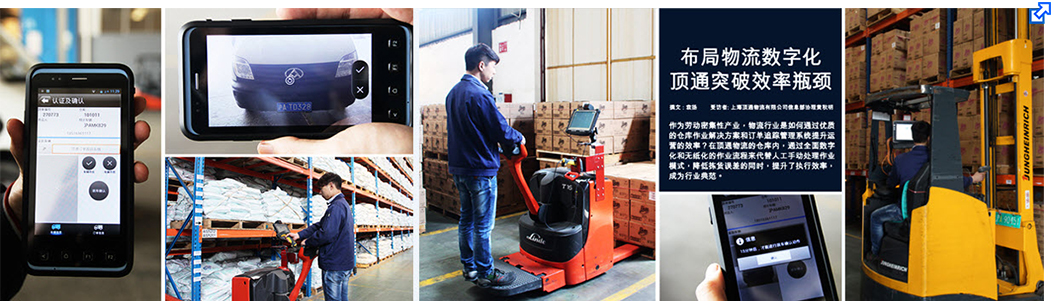

Paperless Process, Tingtong Breaks Through the Efficiency Bottleneck

Although Tingtong used barcodes to manage goods and storage locations in the past, warehouse staff still had to get off their trucks to scan the barcodes.

Operating this way intangibly increased safety hazards and working time; thus, warehouse operating efficiency was not improved fundamentally and picking or restocking operations were still highly dependent on the familiarity of warehouse personnel.

Additionally, picking and restocking operations relied heavily upon paper documents and data entry took a great amount of time. On-site warehouse workers even had to wait 2 hours before receiving the newest printed documents, thereby delaying subsequent processes. Real-time inventory updates were also hard to achieve.

Advantech's Digital Logistics and Fleet Management large account customer service representative Yi Ren Huang said:

“Our warehouse operation optimization solution uses large barcode scanners, which eliminates the need for warehouse workers to get out of their trucks to scan barcodes. This not only reduces operating time but also eliminates safety risks when scanning barcodes. The onboard computers can receive commands from the control center and return results via the wireless network, and even plan the tasks and paths workers should follow. Thus, when warehouse operations are no longer limited by the level of experience of the staff, space and time efficiency can be improved and the accuracy of the work performed is ensured. Since onboard computers can also return job results, warehouse workers no longer need to waste time on waiting for printed documents and administrative staff in logistics centers can also save a lot of time on preparing reports. Every day before 08:00, the control center can obtain accurate inventory information of the previous day up until 24:00.”

Real-Time Order Tracking Freight Management to Enhance Efficiency

After the goods leave the warehouse, the control center must track the driver's driving behavior, route, and whether the order was delivered.

In the past, after the cargo was loaded, the control center had no way of tracking the truck's location, and therefore could not determine whether the driver arrived at the delivery location. Due to various reasons, the driver sometimes cannot get the signed delivery documents back in time. Thus, keeping a photocopy of the proof of delivery is conducive to future verification and recovery.

In customizing the order tracking management system for Tingtong, Advantech used advanced wireless transmission and GPS positioning technology with handheld computers to realize location tracking throughout the driver's trip, order tracking, and other business needs. Drivers can also take photos of the delivery receipts with the handheld computer. The photos are sent back to the control center immediately.

The control center then knows the status of the deliveries in real time. If the need for re-deliveries or returns arises, drivers can report this information to the control center via the handheld device. The control center can then monitor the relevant information to handle re-deliveries and returns through the order tracking system.

This process not only reduces the amount of work for processing re-deliveries and returns but also reduces the disputes that may arise during this period. When other abnormal occur during the transport of goods, the logistics center can receive the related information immediately and create countermeasures through the handheld computers.

Advantech Solution Improves Operational Efficiency

When talking about Advantech's digital logistics solution, Assistant Vice President Mr. Huang said, “A digital and paperless workflow such as this not only replaces previous tasks that relied heavily on manual processing but also greatly reduces picking errors and improves efficiency. In the past, it was very difficult to monitor drivers'driving behavior, route, and the delivery situation between the drivers and stores. Now, we can monitor all of these situations in real time.”

“Prior to introducing Advantech's solution, we used many other suppliers. However, Advantech was the only one who could provide an integrated solution including software, hardware, and project management, and only Advantech has a nationwide service network that can match our national logistics network. Advantech is a publicly listed company in Taiwan whose brand and reputation are also superior to other suppliers. In fact, after introducing Advantech's solution, Tingtong Logistics' operational efficiency improved.”

Visit Advantech's Logistics & Warehouse Management Solutions

Related White Papers

Supply Chain Management in the Automotive Industry

In this paper, we discuss why industrial computing plays a major role throughout the entire automotive supply chain, from allocation and storage of raw materials and components to production and delivery to timely spare parts procurement. Download Now!

Global Intelligent Long-Haul Trucks Solution Realize Driver Behavior Management

This paper details Advantech's fleet management solution which provides long-haul trucks with real-time wireless access and increases delivery efficiency and fuel savings while reducing insurance costs. Download Now!

Cold Storage “Last Mile” Logistics

This white paper describes how to profit from cold storage 'last mile' logistics business benefits including lowers operating costs, reducing system downtime and interruptions, increasing productivity, greater product longevity, improved data integrity and inventory management. Download Now!

Supply Chain Transformation Relies on Technology Deployment

This whitepaper shows industry survey results from adopters in supply chain management and offers insights on ROI for supply chain investment, the data offers a comparison to your own status and stacks it against transformation trends. Download Now!

More Advantech Resources

Article topics