The Problem: An off-highway vehicle manufacturer needed the flexibility to gradually scale a new line as production increased, without paying for any conveyance they didn’t need.

The RedViking Solution: A Wingspan Battery-free AGV assembly line that grew production by 200% in 2 years with no increase in staff or floor space. The line has been successfully rerouted over a weekend.

A global manufacturer of construction vehicles wanted to significantly increase throughput, but they didn’t want to spend capital equipment budget before it would be fully productive. Because durability is a corporate value, they wanted an assembly line that would have the lowest cost of ownership over its lifetime.

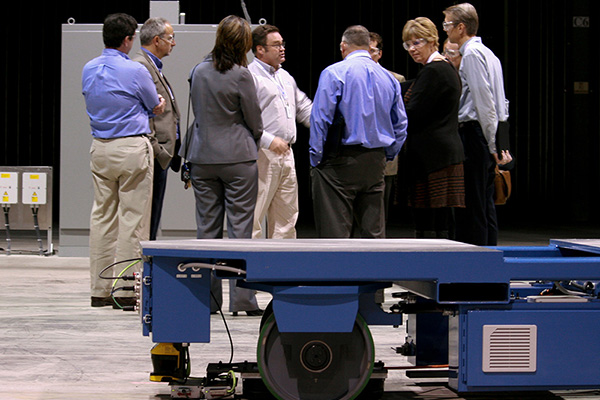

RedViking designed and built a Wingspan Battery-free Automated Guided Vehicle (AGV) assembly line that allowed them to buy only the AGVs that they needed, with the ability to seamlessly scale in the future. A universal AGV was designed for a wide variety of off-highway vehicles so that the factory can respond quickly to new production requirements.

Today the plant has tripled its capacity by gradually adding AGVs, without adding staff or floor space. Where a chain-based conveyor would have been scrapped and replaced, simple tooling changes to existing AGVs can handle new vehicle models. You can see a time lapse video of the AGV line here.

Installing a Wingspan Battery-free AGV conveyor system requires far less material, labor and hazardous equipment than traditional conveyor systems. Instead of installing thousands of pounds of steel tracks, we cut two shallow channels into an iron-free floor, laid data and communications cable, then epoxied over and sanded to a flat floor finish.

Where paths merge and separate, no multi-track system, unchaining or lift transfer is required – software and controls direct the AGVs’ path along one of the quickly changed in-floor paths. All AGVs were proved out on the RedViking test track prior to shipment, removing risk from the AGV setup during installation.

The AGVs continuously receive power whether in station or moving through production. Custom designed quick connections travel with the AGV for use during vehicle hot test, without any need for additional power. Because the AGVs can be customized to carry specific connections, they can eliminate a number of outside systems.

The end result is a flexible manufacturing line driven by production requirements, powered by IPT® and managed with software and controls. This highly portable conveyance becomes virtually invisible by providing 360 degree access to the vehicle under production. Today this safe, clean, quiet assembly line has significantly improved capacity utilization while proving itself to be highly scalable.