Handling Specialty Manufacturing

Grimsby, Ontario, L3M 4G1

Canada

1 (905) 945-9661 1 (800) 559-8366

www.handling.com Handling Specialty Manufacturing Company Profile

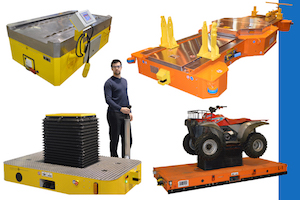

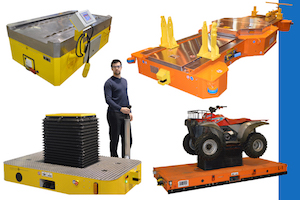

Handling Specialty’s autonomous guided vehicle is feature rich and designed for those focused on continuous improvement. Advanced manufacturing and materials handling industries find countless uses for automatic guided vehicles.

The company has the capabilities to design a custom engineered automatic guided vehicle for virtually any application. Custom tooling is also considered in the design process along with weight capacity, safety requirements and the AGV’s application whether it be for assembly or another function. The custom tooling can range from support struts to roller-ball platforms, rotators, conveyors, and even scissor or mast lifts perfectly tailored for your application, and programmed to your specific requirements.

Flexibility to alter the assembly floor is another benefit. Now, with smart tape, the AGV uses laser guidance; moving along a pre-determined path set by the tape. This tape can be pulled up with little cost and re-positioned should the needs of the facility’s assembly line change.