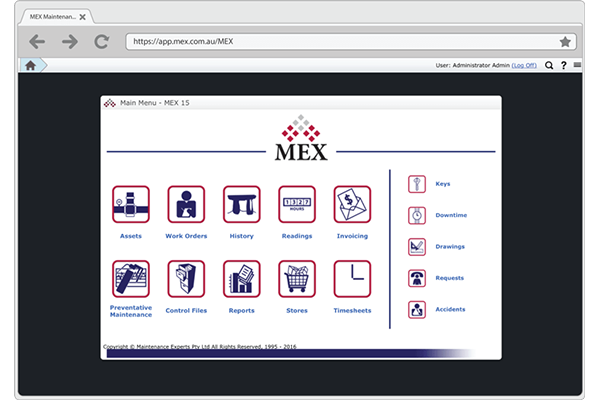

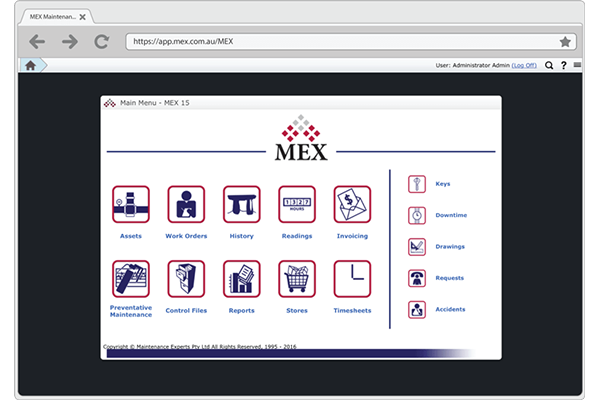

MEX Maintenance Software

Newstead,

United States

+ 61 7 3392 4777 + 61 7 3392 4888

www.mex.com.au MEX Maintenance Software Company Profile

MEX is a Computerised Maintenance Management System (CMMS) designed specifically to manage all your critical assets.

MEX achieves this by utilising simple but efficient maintenance modules that transform your computer into a maintenance control centre.

MEX has the ability to capture comprehensive asset information, manage day to day maintenance workloads, schedule preventative maintenance and inspections, handle automatic stores ordering and produce detailed statutory reports at the drop of a hat.

All in all MEX makes life easier for you and your service technicians on the job.

MEX can help you by taking the stress out of maintenance management.

The all in one digital platform gives you a simple and effective tool to monitor anything and everything that’s maintenance related.

Well-maintained equipment equates to fewer breakdowns and also lower repair and replacement costs – A direct and measurable saving.

With scheduled maintenance and inspections, equipment works more efficiently with reduced breakdowns.

From current jobs, to requests, to historical data: Record all work carried out on equipment and in every detail.

Comprehensive inventory management allows for stock levels to be monitored and replaced on time, eliminating wait times on critical spares.

With the vast amount of equipment information stored against each asset, reports for auditing and analytic purposes are readily available.