East Peoria, Illinois, 61611

United States

www.jtecindustries.com/ Jtec Industries Company Profile

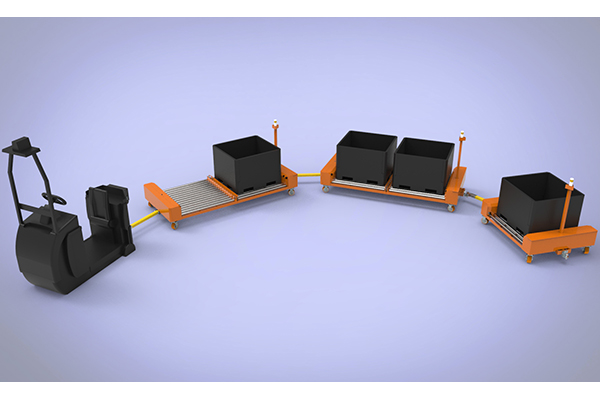

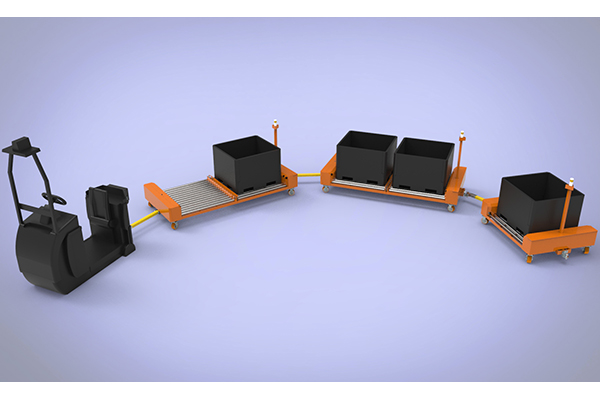

Our CarryMatic automated material movement systems consists of smart carts, smart line transfer stations, proprietary supervisor software and (in manual mode) vehicle interface module (VIM). Cart trains are pulled by an unmanned AGV (auto mode) or manned tugger vehicle (manual mode) throughout facilities, automatically transferring cargo on and off of carts and stations at designated destinations.

This is a totally hands-free solution that eliminates fork truck usage for deliveries. In auto mode, AGV’s or mobile robots are used to pull carts with no operators. The AGV drives a pre-determined route with a train of carts and transfers materials via powered rollers at appropriate locations.

Deliveries are pre-programmed through J-tec’s CarryMatic software, which communicates with the AGV. Highly visible stack lights on each cart and station indicate all material transfer activity. CarryMatic software and hardware can be integrated at multiple levels of operations.

In manual mode, tugger operators drive predetermined routes and use a tugger-mounted touchscreen to facilitate transfers. CarryMatic systems eliminate common ergonomic safety risks often associated with lifting and bending. CarryMatic ensures accurate and timely deliveries of materials to appropriate locations, on schedule, maximizing productivity and lineside space. Best yet, CarryMatic adds to Jtec’s innovative solutions supporting fork-free initiatives.