Not every operation reuses wood pallets, meaning that certain recipients must break them down for discarding—and risk worker injury—or pay a third party to dispose of them. And those recipients, including city and state government facilities, educational institutions and hospitals, are now pushing back on shippers to request that bulk shipments be delivered on recyclable, corrugated pallets instead, says Adam Pener, president of Green OX Pallet Technology.

“If these end users can award a supplier a $1 million contract to provide milk in a specific type of packaging, they can also mandate the type of pallet it’s shipped on,” Pener says, “and these institutions are more frequently requesting corrugated pallets.”

Green OX’s industrial strength corrugated pallets, engineered to handle up to 1,700 pounds (and currently in testing at 2,000 pounds), are fully recyclable. The pallets can be manufactured in a variety of sizes to accommodate any load, and optionally coated for water resistance while retaining their ability to be recycled.

One of the biggest advantages, Pener adds, is that these pallets ship flat for assembly at their point of use. “We can ship 2,000 unassembled on a truck—five times more than a truckload of wood pallets, a shipment that is mostly air. We also provide them from any U.S. corrugated manufacturer, making them cost effective and cutting the number of truck shipments by up to 80% for the front-end distribution segment.”

In addition to the pallets, for operations needing to assemble high volumes and for whom it’s not feasible to build that many by hand, Green OX has teamed up with ProMach’s Edson Packaging Machinery to develop a 700-square-foot machine that assembles as many as 250 Green OX pallets per hour.

“Currently, there are an estimated 10 billion pallet shipments per year in the United States. At an extra 40 pounds per pallet for wood versus corrugated, that’s 400 billion pounds of pallet weight to ship the same products—and that weight contributes significantly to shipping costs and fuel expenses, as well as to wear and tear on vehicles and roads,” Pener says. “For these reasons, we’re starting to see corporations, as well as policy

makers, show an interest in corrugated pallets.”

View Pallets Products and Accessories

WorldPallet wire mesh pallet

WorldPallet wire mesh pallet

Pallets protected with electro-galvanized finish.

Lumina Pallateer pallet machines

Lumina Pallateer pallet machines

Make your own pallets with molding system.

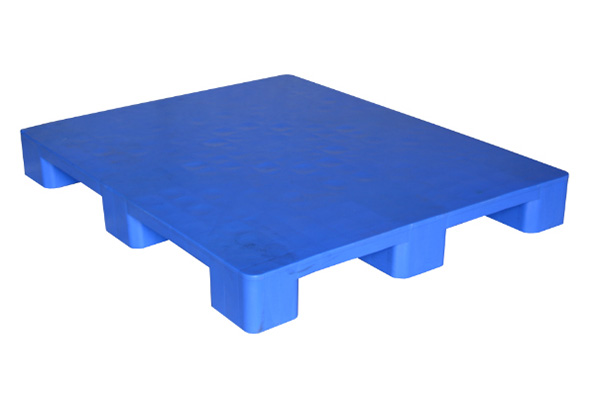

Flat Top plastic pallet

Flat Top plastic pallet

Protect bagged products with flat-top pallet.

Nine-Leg Plastic Pallets

Nine-Leg Plastic Pallets

Pallets come in variety of configurations.

Anti-microbial additive

Anti-microbial additive

Additive for pallets enhances sanitation.

Steel Pallets with Galvanized Finish

Steel Pallets with Galvanized Finish

Load steel pallet with heavy, dense products.

Article topics